Anodizing of Aluminum Ordinances for the Military

Our ability to meet various Mil-Spec standards has allowed us to take on complex coating projects, further expanding our diversity and ability to serve our customers. The project highlighted here is an ordinance component and was fabricated from 6061-T6 aluminum, its conical shape measured under 8" in diameter. The customer's specifications required that the processes used be in compliance with MIL-A-8625F, Type II - Class 2 and MIL-STD-1504C.

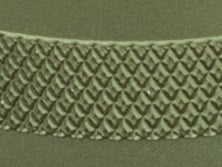

The coating process required that the parts be media (grit) blasted to prepare the surface for the subsequent steps. Further surface impurities were removed using an aqueous cleaning method; fully prepped and cleaned we applied a type II anodize, then dyed the product Olive Drab and sealed them . Various in process inspections were performed to ensure that all of the standards that the customer required were met.

To learn more about this project, or the process used to coat it, see the table below or contact us directly.

Ready to get started?

HIGHLIGHTS OF THIS CUSTOM STAINLESS STEEL PASSIVATION PROJECT

- Product Description

- These ordinances are used in the military.

- Custom Anodizing Capabilities Applied/Processes

-

Media Blasting

-

Aqueous Cleaning

-

Olive Drab Anodizing

-

Type II Anodize

- Equipment Used to Manufacture Part

- Dedicated Rack Anodizing Line

- Overall Part Dimensions

- Under 8" Conical Shape

- Tightest Tolerances

- Meets Mil-Spec Tolerances

- Material Used

- Aluminum 6061-T6

- Material Finish

- Non-Reflective Matte Olive Drab

- Industry for Use

- Military

- Defense

- Standards Met

- Customer Specifications

- MIL-A-8625F, Type II - Class 2

- MIL-STD-1504C

- Product Name

- Ordinances

.png?width=384&height=95&name=Dise%C3%B1o%20sin%20t%C3%ADtulo%20(2).png)